TS-550 Evo Fuel Management System

For the customers who require highly evolved user interface for automatic tank gauging. Highest rated continuous 24 hours leak detection (SCALD) in the industry. Density measurement and alarm capabilities. Patented Autolearn™ electronic line leak detection for high throughput lines. Complete web interface and email capabilities. Turbine pump interface, intelligent STP control. Programmable one touch buttons

Colibri Tank Monitor

Colibri is ideal solution for fueling station owner who re quires basic, cost effective, straight forward functionality in a fuel inventory monitoring system. This system monitors fuel density and inventory levels in up to 6 tanks and provides accurate, reliable information without manually taking tank readings. Additional features communicate the status of tank contents, including volume, temperature, mass, water level and continuous tank leak detection. The web interface feature allows authorize users access to tank information from any computer connected to the internet or wide area network, as well as custom alerts can sent to email or mobile.

ProGauge Maglink LX and XMT-SI Fuel Probes

The system by default supports 16 tanks. Leak detection (Dynamic & Static), deliveries, trends, historic events/alarm recording and notification, reconciliation, shift management, reports, etc. Industry standard POS communication protocol (Fusion Box, DOMS, Namos, etc). Web access and WiFi connection, color resistive 7” touch screen display, GSM/GPRS, Radio wireless, 4 low programmable relays, 6 digital/analog inputs, RS48 – RS232, Ethernet port, USB device, Can-bus port.

XMT-SI Fuel probes have point-to-point and multidrop connection, product and water detection at 0.01mm, measuring accuracy better than ±0.5mm, fuel temperature detection, stainless steel shaft with leak detection capability, unique battery back-up option, intrinsically safe under ATEX 2014/34/UE

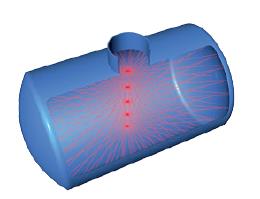

ProGauge 3D Laser Tank Calibration

This innovative automatic tank calibration system utilizes a 3D Laser to provide an accurate strapping table for the console or point of sale. It is safer, faster and more cost-effective than the traditional method used. It is ATEX certified and metrologically approved.